RSI Overhead Conveyor Systems

RSI offers a variety of quality overhead monorail conveyor systems and components. We look forward to assisting you in selecting the right equipment for your application. Also, see our “selection guide” below for additional information.

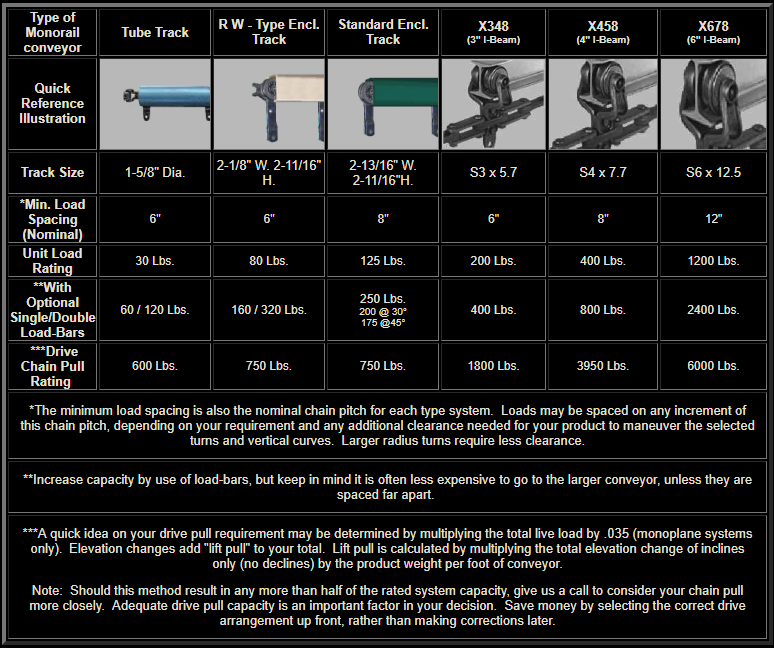

Selection Guide for Chain Conveyor Applications

See the following selection guide to help determine which type of overhead monorail conveyor system best suits your application, depending on maximum unit load, part spacing and chain pull capacity requirements.

BASICS

New High Performance e-Chain

Advantages:

Longer Chain Life

Smoother Operation

Quieter Operation

Greater Reliability

Patent Pending

Enclosed Track & Chain Benefits

6″ Chain Pitch Versus 8″ Chain Pitch

-Increased Throughput

-Less Wear in Curves

-Longer Chain Life = Reduced Cost

Hardened Pin Chain Connection

-Reduces Wear at Connection Point

-Removable Cotter Pin for Easy Replacement

-Increased Chain Life

7 Gauge Track Thickness

-Industry’s Heaviest Track

-Increased Life

-Increased Capacity

RSI Manual Monorail Enclosed Track Conveyor

Straight Track, 3/16″ thick, the heaviest in the industry, stocked in 10′ lengths.

Horizontal Curves, 3/16″ thick, 90°

Frog Switches

VMTs-automatically raise or lower product

Carrier Insert Section

Welding Jigs

Carrier Assemblies

Turntables

Range from 125 to 1,000 pounds

Maintains Quality

RSI Manual Monorail is a hand-push transport and storage alternative to manual re-handling of product. This decreases the potential for loss or damage.

Utilizes Space Efficiently

RSI Manual Monorail frees up vital floor space, providing product movement throughout a facility and allowing for organized product flow.

Maximizes Product Storage

RSI Manual Monorail provides dedicated storage in user specified area. This system eliminates wasted space and efficiently stores product in an organized manner within the same work areas, day after day.

Reduces Product Damage and Worker Injury

Since product is suspended from a RSI Monorail carrier, manual re-handling of product is kept to a minimum, reducing the chance of product damage. VMTs automatically raise and lower product, eliminating injuries related to lifting and bending.

Increases System Life

RSI Manual Monorail’s enclosed track protects carriers and runways from dirt and other contaminants. In addition, RSI Manual Monorail’s sliding frog plates support loads through switches providing both smooth travel and longer switch life.

Facilitates Upgrades

RSI Manual Monorail components are compatible with most conveyor systems. As a result, RSI Monorail can be upgraded when needed.

Photos courtesy of RW

RSI Monorail Enclosed Track Conveyor

Using standard modular components constructed for long life, RSI conveyors solve a variety of manufacturing problems. From simple, in-line finishing systems to complex storage and retrieval systems, RSI is an efficient and economical solution.

Straight Track, 3/16″ thick, the heaviest in the industry, stocked in 10′ lengths.

Welding Fixtures

Horizontal Curves, 3/16″ thick, 90′ flame hardened

Top Vertical Curves, 3/16″ thick, 90 degree, flame hardened.

Bottom Vertical Curves, 3/16″ thick, 90 degree, flame hardened.

Conveyor Chain, 6″ pitch.

Take-up Assembly.

Inspection Section.

Chain Oiler.

Standard Drive Packages.

Load Pendant Attachments.

75 lbs per load

Standard drive packages up to 750 lb. chain pull

Protects Product and Parts.

RSI’s enclosed track protects product from contamination that typically falls from open chain conveyors. RSI also protects the chain from airborne dirt, abrasives and solvents, prolonging chain life.

Simplifies Installation and Maintenance.

RSI’s enclosed track is constructed of standard, modular components that guarantee easy installation, modification and maintenance. Standard components also guarantee quick accessibility through local stocking distributors.

Increases Throughput.

RSI’s enclosed track chain has a pitch of 6″ and is shortest in the industry. This allows up to 33 percent more productivity. The pitch of our chain allows you to space load pendants closer with less wheel loading, allowing for more product throughput. This shorter pitch also allows for tighter radius horizontal curves.

Maximizes Floor Space.

RSI’s standard 1′-6″ horizontal and 2′-0″ vertical curves can make tight changes in direction and elevation, freeing up valuable floor space for other assembly and storage operations.

Facilitates Upgrades.

RSI’s enclosed track was designed to meet manufacturers’ changing needs. As a result, it is the only overhead chain conveyor that can be upgraded to a power and free system utilizing all existing components.

Reduces Product Damage.

Because RSI Enclosed Track can transport product anywhere, product handling and damage are kept to a minimum.

RSI Dual Track Power & Free Conveyor

RSI Dual-Track Conveyors combine power and free capability with a side-by-side track configuration. RSI Dual-Track offers the ideal medium- to high-capacity solution where limited overhead space is available for product storage and transportation.

RSI Dual-Track can be built from pre-existing systems, such as Manual Monorail and Monorail. Once a Manual Monorail or a Monorail chain conveyor system is in place, standard in-stock parts can be added to create a RSI Dual-Track power and free system.

Eleven Standard Monorail Components

RSI Dual-Track uses the same standard components as our other chain conveyors.

Eight Standard Manual {non-powered} Components

RSI Dual-Track uses the same standard components as our other standard monorails.

Control Systems

RSI Dual-Track is available with a variety of state-of-the-art control components, ranging from simple PLC-based controls to complex PC-based routing and tracking systems.

Capacities

RSI Dual-Track combines a 3/16″ plate steel load track with carrier handling up to 1,000 lbs. for maximum flexibility.

Switching

RSI Dual-Track provides switching into and out of main line of travel in greater frequency (at closer load centers) than other power and free designs.

Range from 125 to 1,000 pounds

Optimizes Low Headroom

Because of its side-by-side configuration, RSI Dual-Track can be installed in facilities having insufficient headroom for other power and free equipment.

Increases Throughput

With controlled accumulation, RSI Dual-Track eliminates the typical wait time associated with storage banks.

Utilizes Space Efficiently

RSI Dual-Track minimizes floor space requirements by storing work-in-process overhead, calling it down in the quantity and order needed at each operation.

Controls Production Rates

RSI Dual-Track optimizes production by ensuring that the right parts arrive at the correct operation in a continuous flow, especially when rates of production differ between operations.

Maintains Quality

RSI Dual-Track eliminates product re-handling and manual transporting by integrating finishing and assembly processes into one material handling system.

Boosts Efficiency

RSI Dual-Track maintains a traveling record of work-in-process, logging information on where product has been and where defects may have occurred.

RSI Over-Under Power & Free Conveyor

RSI Over-Under conveyors combine power and free flexibility with a heavy duty over and under configuration. Utilizing the time proven effectiveness of Monorail, power conveyors and the durability of two 3″ toe-to-toe load channels, RSI Over-Under is the ideal high-capacity solution for transporting and storing work in process.

Manufactured and stocked in modular components. RSI Over-Under is pre-welded at the factory to ensure unparalleled precision and quick turnaround on fast-track projects.

Eleven Standard Monorail Components

RSI Over-Under utilizes the same standard components used in our chain conveyors.

Rugged Design

RSI Over-Under load track consists of two 3″, 4.1 pound, toe-to-toe channels for high-wear applications.

Control Systems

RSI Over-Under is available with any of a variety of state-of-the-art control systems, ranging from simple PLC-based controls to complex PC-based routing and tracking systems.

Modular Components

RSI Over-Under components are modular and factory-stocked to minimize lead times for fast-track projects.

Capacities

Single RSI Over-Under carriers support loads up to 1,000 pounds,

Tandem carriers can handle loads up to 2,000 pounds.

Controls Production Rates

RSI Over-Under optimizes production by ensuring that the right parts arrive at the correct operations in a continuous flow, especially when rates of production differ between operations.

Maintains Quality

RSI Over-Under eliminates needless production re-handling and manual transporting by accomplishing finishing and/or assembly processes with a single material handling system.

Boosts Efficiency

RSI Over-Under maintains a traveling record of work-in-progress, logging information on where product has been and where defects may have occurred.

Creates Usable Space

RSI Over-Under frees up valuable floor space for more value-added operations by organizing product flow and efficiently utilizing available space overhead.

Protects Product and Parts

RSI Over-Under uses an enclosed track that prevents contaminants from falling onto the product. It also protects the chain from dirt, abrasives and solvents, prolonging chain life.

RSI I-Beam Monorail Conveyor

RSI I-Beam Monorail Conveyor Systems combine flexibility of design with heavy duty capacity. Utilizing the proven reliability of 3″ and 4″ RSI I-Beam load channels, RSI I-Beam Monorail is an ideal high-capacity solution for transporting and storing work-in-process.

Manufactured and stocked in modular components, RSI I-Beam Monorail systems ensure unparalleled precision, ease of movement and quick turnaround on fast track projects

3″ and 4″ track constructed from high strength 1045 structural RSI I-Beam. Chain is available in X348 and X458 sizes.

All chain is drop-forged and rivetless construction.

Trolleys are available in sealed or open bearing designs.

Standard horizontal roller bank turns available in sizes from 1’6″ radius to 6’-0″ radius.

Standard drive units ranging from 1200lbs. chain pull to 3000lbs. chain pull.

Control systems available from simple manual, PLC-based or complex PC-based to fit your system needs.

Made in U.S.A.

Long service life.

The RSI I-Beam track manufactured of 1045 high carbon steel has outstanding wear and load capacities. The drop-forged trolleys are designed for heavy use with smooth running operation.

Ease of Assembly.

The chain is easily assembled or adjusted without the need for tools. The trolleys incorporate rivetless construction.

Heavy Duty Capacity.

The trolleys and loadbars are available in capacities up to 400# each with 3″ track, and up to 800# each for 4″ track.

Creates Usable Floor Space.

These systems free up valuable floor space for more valued-added operations by organizing product flow and efficiently utilizing available space overhead.

Maintains Quality of Production.

These systems eliminate needless production re-handling and manual transportation by accomplishing finishing, assembly processes and/or storage processes with a single material handling system.