SYSTEMS

Simple

A mobile paint booth at your fingertips. Our retractable and compliant paint booth system can service automotive, commercial and industrial workpieces while retracting to a fraction of its size when not in use. The control panel is conveniently located outside the unit and the cleaned air is easily ventilated through your shop door or window.

Efficient

Our mobile paint booth system arrives assembled at your site and you can be ready to paint the same day. Setup and system maintenance is minimal.

Effective

Revolutionary airflow technology reduces the dry time for waterborne paints, and ensures a safe, dust free environment. There is no air movement along the floor surface and overspray is minimal. The patented air filtration chamber removes over 99% of airborne contaminants. The result is a clean finish, every time.

Specifications

Pure performance. Pure power. All the features of a traditional paint enclosure and more.Performance Moves air at up to 13,500 CFM

Filters more than 99% of airborne contaminant particles

Cross draft airflow creates a wicking process that improves dry times without dirt transfer

Power 30 amp 220 V single phase power

Two 1.5 horsepower motors

Two airspeeds one for painting process and a second of drying process

Mobile Retractable and moveable

Ventilation Vent to outside

100% evacuation of VOCs

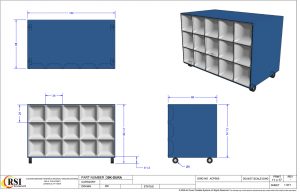

Dimensions Filtration Unit 70 x 80 x 50 in.

Enclosure Extended 24 x 14 x 9 ft.

Enclosure Retracted 4 x 14 x 9 ft.

Optional* Duroair Fire Suppression and Exterior Lighting

* In order to be compliant with NFPA regulations fire suppression is mandatory.

Compliance

A qualified leader in environmental and safety compliance.

Our mobile and retractable paint booth systems, safety and environmental compliance is at the core of our business. Our paint booth systems meet the requirements of a spray booth facility and our team can help you work with your local regulatory body.

CSA SPE-1000 Model Code for the Field Evaluation of Electrical Equipment

NFPA 33 Standard Spray Application using flammable or combustible materials

NFPA 17 Standard for dry chemical extinguishing systems

NFPA 701 Standard methods of fire tests for flame propagation of textiles and films

ONT OHA ONT

OHSA O.Reg 851 – 63 Industrial establishments – Ignition or Explosive

ONT OHSA O.Reg 851 -65 Dust – Ignition or Explosive

ONT OHSA O.Reg 213 Construction Projects (5.12 Fire Code – Spray Operation)

OSHA 29CFR – 1910.107 Spray Finishing using flammable and combustible material

OSHA 29CFR – 1910.94 Ventilation

EPA 40CFR – Part 63.11173 Spray Finishing Requirements

Filters

A superior filter is critical to performance. ‘Paint Pockets® filters are the best performing, single-stage overspray arrestor, bar none. Enhance your finishing operations and minimize filter changing down time and expense.

Paint Pocket Type White

First Stage Pocket Filter 20 x 20 in. X17 in. deep

Second Stage Filter 34 x 70 in.

Filter Change Requirements 480 hours at 1 quart paint / per day (estimate)

Filter Installation Instructions included with filters

Research & Development

Research & Development is at the core of our technology. Our team is dedicated to understanding and responding to the changing needs of our customers, regulations and the environment, in turn enabling you to meet the needs of your clients. Our team of engineers works together in a dedicated facility to develop airflow and filtration technology solutions, through continuous improvement of existing products, and innovation. All systems and products are tested and certified at the highest level by third party agencies and engineers.

Frequently Asked Questions

Sales Questions

Q: What is the process to purchase a unit?

A: Please contact RSI at 502-213-3865 to start the process

Q: What is the lead time to purchase a unit?

A: Lead time will be approximately four to six weeks.

Q: What different models are provided?

A: With our modular design and airflow expertise, we can provide any size enclosure and will match the airflow to provide the perfect quality and compliance. Our standard size system includes a 13,500 CFM exhaust system with a variable frequency drive (VFD) control and a retractable enclosure with the dimensions of 9.5’H x 14’W x 24’L which retracts to 4’L. We have also manufactured a 25,000 CFM exhaust system with VFD controls and a 16’H x 16’H x 45’L retractable enclosure. Our largest enclosure quoted is a 80,000 CFM exhaust system with VFD controls and a 20’H x 40’W x 80’L retractable enclosure.

Q: What is the warranty on the unit?

A: RSI offers a limited warranty which is available upon request. Please contact RSI at 502-213-3865 for a copy of the warranty, to register your warranty or for any warranty claims.

Q: What options are available with the unit?

A: Available as an option is a Kidde/Badger approved retractable fire suppression system which is required in order to meet NFPA 33. Please contact RSI at 502-213-3865 for a quote.

Code Compliance Questions

Q: Does the system meet the requirements of NFPA33 – Spray Operations.

A: The Authority Having Jurisdiction always has the final decision. We understands the importance of meeting national standards and has worked with third party engineers to ensure safety and compliance. RSI is able to provide engineer stamped documents showing that with the recommended fire suppression system, requirements of NFPA 33 are met.

Q: Is fire suppression required? If so, what is recommended?

A: In order to meet NFPA 33 the Kidde/Badger fire suppression system is required. RSI provides a fire suppression system as an option. It is recommended that customers review local fire codes and speak with the local fire inspector for an official opinion of fire protection.

Q: What national codes does the RSI system meet?

A: The RSI system is compliant with the following regulations:

• NFPA 33 Spray Application

• NFPA 17 Dry Chemical Extinguishing Systems

• NFPA 701 Fabric – Flame resistance

• OHSA O.Reg 851 – 63 Ignition or Explosive

• OHSA O.Reg 851 – 65 Dust – Ignition or explosion

• OHSA O.Reg 213 – 5.12 Fire Code – Spray Operation

• OSHA 29CFR – 1910.107 Spray Finishing

• OSHA 29CFR – 1910.94 Ventilation

• EPA 40CFR – Part 63.11173 Spray Finishing Requirements

• CSA Certified

Q: What government certifications are required before using the unit?

A: Installing a paint booth requires permits from your local jurisdiction officials. The Authority Having Jurisdiction (AHJ) is usually your local building inspector or fire inspector. The AHJ will have the final authority to provide your permit.

Q: What is the evacuation rate of VOC’s?

A: Venting, installed to meet local jurisdiction requirement is required. Evacuation rate of VOC’s is 100%.

Q: What is the capture rate through the two filters?

A: At the recommended airspeed using the recommended filters, the capture rate of airborne particulate is 99.2%.

Q: What safety equipment is required when using the unit?

A: The user should follow Personal Protective Equipment standards for spray operations.

Setup Questions

Q: How is the unit delivered?

A: The exhaust system will be shipped assembled requiring only a hard wire electrical hookup. The enclosure can be assembled in a morning and fully functional in the afternoon. The system will be delivered by approved transportation companies. Customer pays for shipping costs.

Q: What is required to unload the unit when delivered?

A: The unit and enclosure will be delivered using a truck with a lift gate or a flatbed truck where a fork lift will be required for delivery. Delivery method will be confirmed with customer at time of purchase.

Q: What power source is required?

A: The unit is manufactured with 220V single phase 15amp electronics. 208/230/480V or 575V three phase is available upon request.

Q: What electrical set up is required?

A: It is recommended that the customer hard wires the exhaust system to the electrical panel. This work must be completed by a licensed electrician.

Q: What venting is required?

A: It is recommended that the customer uses a local contractor to install the duct work. Duct work must be installed to meet local bylaw regulations. In general there is a requirement of one hour burn through rated material. RSI will confirm the size of duct at time of quote.

Q: What lighting requirements are recommended?

A: In general, shop lighting is sufficient. As an upgrade, it is recommended that the customer installs T8 daytime overhead lighting with mobile lighting on the side. It is to the digression of the customer.

Q: What is the setup time of the enclosure?

A: The 13,500 CFM system can be delivered in the morning and fully functional in the afternoon. Minimal setup time is required.

Q: Will you provide installation?

A: Installation is provided as an option upon request. If the customer does not wish to select the installation option, a customer service representative will be available to assist customers with any questions by phone.

Operations Questions

Q: Does the unit produce negative pressure in the shop?

A: Yes. As a cross draft booth, the system uses shop air as the intake air and therefore produces negative pressure within the shop. In order to meet code, an adequate amount of tempered air must be provided back into the shop environment to create a neutral air environment.

Q: What are the dimensions of the standard enclosure and unit?

A: The unit has dimensions of 72”x54”x80” and enclosure has dimensions of 9.5’H x 14’W x 24’L when the enclosure is fully extended. The enclosure retracts to 9.5’H x 14’W x 4’L. With our modular design, We can design your enclosure to meet the requirement of your spray area and will match the airflow to provide the perfect quality and compliance.

Q: How many CFM’s does the unit pull?

A: During the paint cycle the unit pulls at 8,000 CFM. During the dry cycle this is increased to 13,500 CFM.

Q: What are the fans specifications?

A: The 13,500 model uses a 30” diameter fan with a 3HP motor on a variable frequency drive allowing the user complete control over the airflow. The 25,000 CFM model uses a 42” diameter fans with a 5HP motor on a variable frequency drive.

Q: What are the dry times?

A: Our cross draft airflow creates a wicking process that decreases dry times without dirt transfer.

Q: Can the air be vented in commercial, main street areas?

A: Air can be vented with appropriate setbacks. To be reviewed by local jurisdiction/local bylaws.

Q: Are there any issues relating to overspray?

A: As a result of the patented tapered airflow design, overspray is minimized as the airflow is directed down the center of the enclosure with almost no airflow along the sidewalls or floor. The overspray is therefore caught into the airstream before reaching the walls.

Maintenance Questions

Q: How often do the filters need to be changed?

A: The exhaust system provides a manometer to identify the filter load and when filters must be changed. In general, customers are changing their filters every 3-4 months depending on use.

Q: How do you order new filters?

A: In order for the warranty to remain valid, filters must be ordered through the manufacturer.

Q: How often does the PVC fire rated vinyl used on the enclosure need to be changed?

A: Using proper paint methods, the PVC Fire Rated Vinyl will last approximately 5 years. New PVC Fire Rated Vinyl can easily be ordered from RSI and installed in 1-2 hours providing the look of a new enclosure.

Q: How do customers order aftermarket parts?

A: The customer should contact RSI at 502-213-3865 for approved aftermarket parts.

Q: Is there customer service via phone, email or web?

A: Yes. Customer Service contact at 502-213-3865,