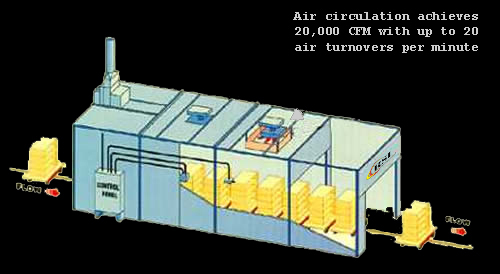

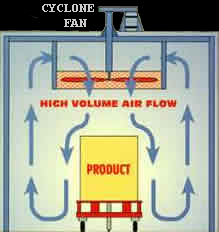

The Cyclone Oven is a RSI custom design, perfect for the wood, metal and plastic industries. It incorporates high velocity heated forced air to speed the curing process. High volume air circulation facilitates the transport of heat at designated temperatures, accelerating curing cycle times for high solids, waterborne and traditional coating materials.

Curing cycles are accelerated, providing consistency and stability to the finishing process. Cyclone fans can achieve 20,000 CFM and up to 20 air turnovers per minute.

The RSI Cyclone Oven requires less hardware and ductwork, and have the capabilities needed to be incorporated into conveyorized applications.

All RSI Ovens comply with the NFPA, IRI and FM insurance regulations. The RSI Cyclone Ovens are available in gas, steam or electric heat

Conventional Drying Ovens deliver heat at designated temperatures thereby accelerating curing cycle times for high solids, waterborne and traditional coating materials. High volume air flow delivers up to 20 air turnovers per minute. Excellent for case goods, millwork, or other applications. Entry and exit vestibules help minimize heat loss from the oven area. Manufactured with 20 gauge aluminized interior and exterior separated by 3” of insulation. Prewired and tested control panel. Available in natural or LP gas, steam, or electric designs.