RSI Air Makeup Systems, when supplied with the fabric distribution duct, will have a direct impact on employee comfort, morale and productivity. A RSI Air Makeup System can be designed utilizing a variable inlet air damper to effectively control the level of positive pressure in a finishing environment. A more precise method of control utilizes a variable speed AC inverter to precisely control the fan motor speed in response to the pressure sensor placed in the finishing room. As the demand for replacement air increases as a result starting or stopping a spray booth, the air makeup unit responds almost immediately by varying the amu fan motor speed. This important option prevents an undesirable positive or negative pressure situation from occurring. RSI can also supply combination systems incorporating both 100% supply units in conjunction with variable supply units to satisfy virtually any replacement air requirements.

Improve Quality and Productivity

Most people take air for granted. Did you know that the quality, temperature, contaminants, and method of movement of the air in a finishing room could have a direct impact on employee comfort, morale and productivity?

RSI has a history of being able to offer a variety of solutions to problems like these and others to solve your replacement air, night and weekend heating and air distribution requirements.

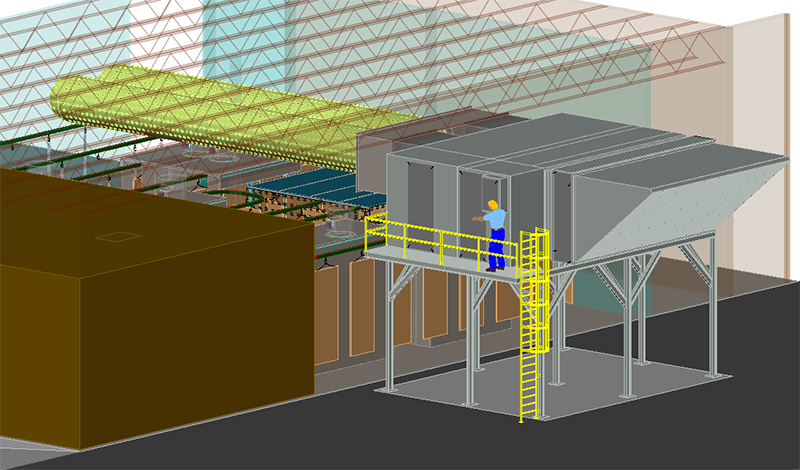

RSI can offer a variety of systems ranging from a variable displacement air make-up system, 100% supply system, either direct fired or indirect fired, and a precisely controlled and integrated air distribution network that will greatly improve employee productivity by improving air quality, controlling airborne contaminants, and increasing employee comfort. RSI also offers a variety of control options that allow you to customize your system to provide the level of precise control that your process may demand.

Look to RSI today for help with all of your air make-up and air distribution requirements.